The Process

The Clay

Andrew makes his clay from using dry materials and some local red clay. The process starts with 30 gallons of water being dumped into a large container and then the ingredients are added one by one until the recipe is complete. The clay is then mixed with a drill and poured into drying racks. The clay will sit in the racks for up to 4 weeks until it has dried to the right consistency for turning on the wheel. Andrew mixes his clay like this because it creates a clay body that is fully saturated with water and therefore creates a better throwing clay body. A ton is made to supply enough clay for six months of turning.

The Cycle

Carolina folk pots and folk pottery from England inspire the pots. The throwing technique and discipline was learned during a two-year apprenticeship with Matt Jones. Matt is a former apprentice of Connecticut potter Todd Piker and North Carolina potter Mark Hewitt. The throwing cycle typically will be a 4 to 6 week process starting with the turning of larger pieces like vases, bowls, and pitchers. Andrew then starts making plates, pie plates, serving bowls and finally finishing with small pots like mugs, small bowls, and bud vases. Once Andrew can pick up the freshly made pots without damaging them, he then decorates each pot and then raw glazes them with a variety of different glazes. The throwing cycle ends with the brushwork decoration being applied to the fully dried pots. With the cycle complete, the kiln is then loaded.

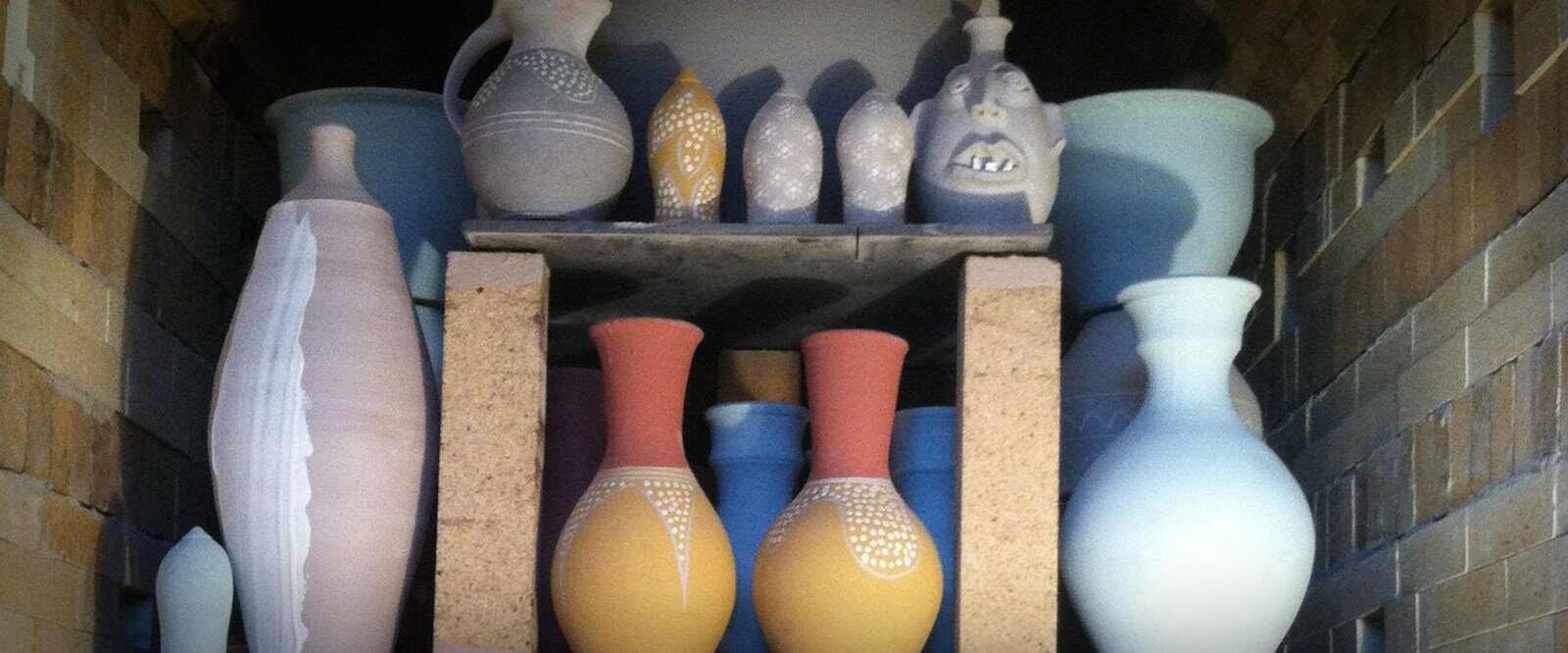

The Kiln

The kiln is a catenary wood fired, cross-draft kiln meaning the firebox is directly across from the exit flue of the kiln. Fellow North Carolina potter and good friend Mark Peters designed the kiln. Mark and I built the kiln in the winter of 2005 with the help of other friends and local potters. The kiln is made of high temperature brick and the arch is made of a high temperature castable or clay concrete mix. Wood for the kiln comes in bundles from a local wood shop that makes molding for interiors. It typically takes 2 1/2 truckloads to fire the kiln. Once the pots are loaded in the kiln, a small burner is placed in the kiln to preheat the pots to 150 degrees Fahrenheit. The firing starts the next morning with a small fire being built and then wood is added over a 17 to 19 hour period until the temperature in the kiln is brought up to 2400 degrees Fahrenheit. Once the top temperature is reached, salt is thrown into the kiln to help flux out the wood ash on the pots and to glaze any raw areas on the pots. The kiln then cools for 2 days and the pots are unloaded, cleaned up, priced, and packed up for sales or gallery deliveries.